News & product updates

Equipment wear monitoring sensors combined with IoT gives visibility of equipment condition straight to your device

Racing speed isn’t everything and many other factors must be embraced between the waving of the green and chequered flags. Gill’s Catch Tank oil level sensor contributes to the win by playing its own important role:

Gill’s race proven sensors have delivered yet again, helping motorsport teams and drivers throughout 2023 to achieve, not only poles and podiums but World Championship wins.

Continuous condition monitoring technique provides manufacturing plants the earliest alerts of wear in critical rotating equipment

We are very pleased to announce that Gill Group has been shortlisted in the Supply Chain Excellence category of the Manufacturer MX Awards 2023!

High numbers of critical and highly loaded gearboxes in manufacturing plants or within conveyor drives in large scale distribution and warehousing facilities, benefit from ferrous debris sensors providing essential real-time insight into gearbox health. Outputs such as Modbus ensure these sensors can be readily integrated into existing systems.

Discover how continuous oil debris monitoring boosts your CBM options. Watch our on-demand webinar for insights into proactive maintenance and increased equipment reliability.

The website has a new modern look, in keeping with the overall Gill company branding.

The main structure of the website has an intuitive user flow.

WearDetect Starter Kit training

Training video to be used with the WearDetect Starter Kit, summarising how the sensor works, how to install it and how to get the best from the sensor to protect critical assets.

Oil debris sensor technology is a growing area of CBM, especially among large manufacturers. Download the report for more information

Gill WearDetect sensors protect critical assets by providing the earliest warning of the initial stages of gearbox failure. Download the brochure to find our more

Low speed gearbox wear monitoring can be difficult with traditional CBM methods. Alternative wear detection strategies can provide early warnings. See case study

Introducing Gill WearDetect - a condition-based monitoring tech that enhances uptime, safeguards assets, and predicts wear trends.

Wastewater level monitoring in sewage treatment plants requires a sensor that can reliably cope with sludge, strong fluid flow while exposed to the environment

Liquid level sensors with marine systems compatibility accurately monitor hovercraft critical fluids

The Large Synoptic Survey Telescope (LSST) will use the world's largest digital camera, requiring continuous refrigeration to -100°C. High performance liquid level sensors are required as part of this cooling system.

Robust, reliable liquid level sensor for defence applications

Download the full guide

There are many advantages of capacitive level measurement technology - here is a short summary of the main benefits...

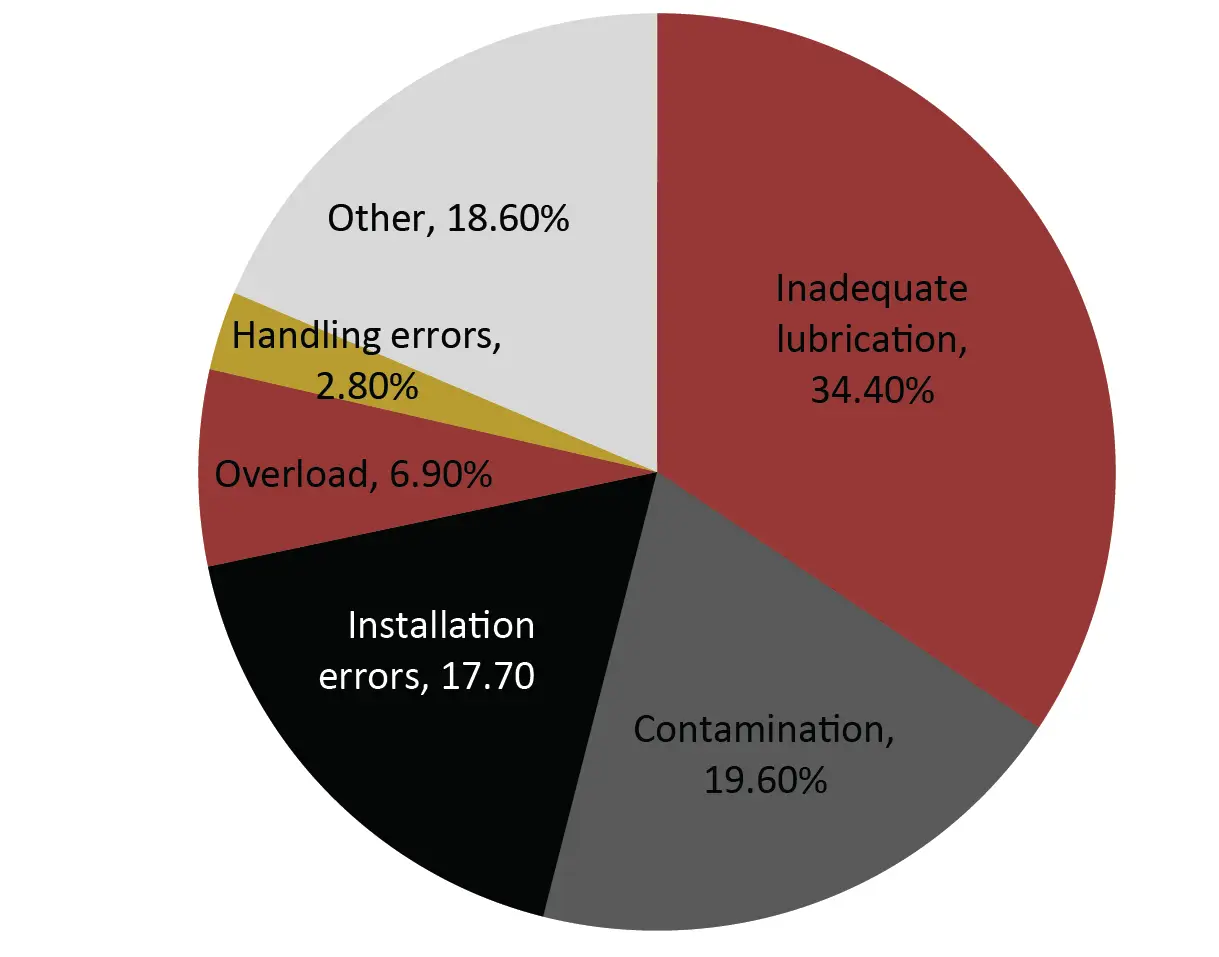

Gearbox failure can cause a complete machinery breakdown, expensive to repair as well as lost output. Common causes of bearing failure in gearboxes include...

All new Gill level sensors come with a secondary output function which operates as a high or low level switch.

Liquid level measurement accuracy and robust construction in a lightweight package

Position sensor replaces potentiometers on tobacco cutting machinery to increase reliability in hostile dusty environment

Oil debris sensors improve gearbox reliability on extrusion machines, providing operators with a clear picture of the health of the extruder

Gill provides bespoke solutions to challenging requirements in the fight against the use of Improvised Explosive Devices (IEDs)

Measuring true water volumes in liquids containing flocculant, agitation, foaming etc requires a level sensor designed to be reliable and accurate under these conditions

Oil debris sensors are a powerful multi-point predictive maintenance tool providing the earliest warning of ferrous wear in wind turbine gearboxes

19 measurement sensors are installed on the supersonic car, chosen for their unrivalled reliability and high accuracy to ensure the car operates as expected

Gill non-contact position sensors have been integrated into an anti-roll bar (ARB) lever assembly in IndyCars to address vehicle handling & improve race performance

WearDetect Oil Debris Sensors can be installed directly out of the box using factory settings to be up and running within a few minutes. For more specific situations or where you have been using WearDetect for some time and wish to tailor the output, WearDetect can be fully optimized to suit your specific situation. Please find below 2 videos showing both these scenarios.

![Supply_Chain_Excellence_-_Finalist_Social_Card[1] Supply_Chain_Excellence_-_Finalist_Social_Card[1]](https://gillsc.com/wp-content/uploads/2023/08/Supply_Chain_Excellence_-_Finalist_Social_Card1.webp)