How -to Guide: Use an Open Collector Output

All new Gill level sensors come with a secondary output function which operates as a high or low level switch.

LevelPro liquid level sensors are used in applications ranging from measuring fuels, oils or coolants in marine vessels and off-highway machinery through to measuring the level of aggressive chemicals within manufacturing processes. Using capacitive sensing technology, LevelPro level sensors provide highly accurate and reliable contact based measurement in a wide range of liquids. LevelPro is selected where long-term reliability and lowest lifetime cost of ownership is important.

Designed & Manufactured by Gill Sensors & Controls in the UK, LevelPro liquid level sensors provide accurate and reliable level measurement in aggressive liquids or liquids operating in harsh environments. LevelPro level sensors use solid-state capacitive technology to sense the level of the liquid. With no moving parts, floats or other mechanical linkages, LevelPro provides excellent long term reliability, accuracy and durability resulting in lowest lifetime cost of ownership.

In addition to liquid level measurement, LevelPro sensors also provide a selectable high/low alarm.

Every sensor is factory calibrated with temperature compensation to provide market leading accuracy in liquid level measurement as well as quick and easy setup.

A tank profiling feature allows LevelPro level sensors to provide accurate tank volume output results even in irregular tank shapes.

Mounting options – a range of standard mounting options is available.

Two output options are available (analogue voltage or current) and LevelPro is compatible with industry standard gauges, PLCs, RTUs and IoT data collection systems. Output voltage 0.25-4.75V (max range 10V). Output current 4-20mA.

Environmental protection IP66, IP68.

LevelPro level sensors have no moving parts and as a result are extremely reliable and accurate, requiring minimum maintenance.

Gill liquid level sensors are supported by standard accessories to assist with specific installation requirements.

The USB to RS232 cable adaptor allows connection of a Gill LevelPro LevelLite or CatchTank liquid level sensor to a computer where the sensor can be quickly configured using GSlevel software. (only the FTDI USB-RS232-WE-1800-BT_5.0 is fully supported – other converters may not be compatible).

Gill Liquid Level Display can be programmed to ‘map’ the tank shape to display true volume rather than simply liquid height.

Provides a real-time quick visual reference and an accurate numerical reading (using 29 bright LEDs and a seven segment panel) with light-sensitive auto-dimming for night use.

Fully programmable with a low level alarm.

Compact and lightweight for easy installation on dashboards and instrument panels (shallow 6mm depth aluminium bezel).

Overview

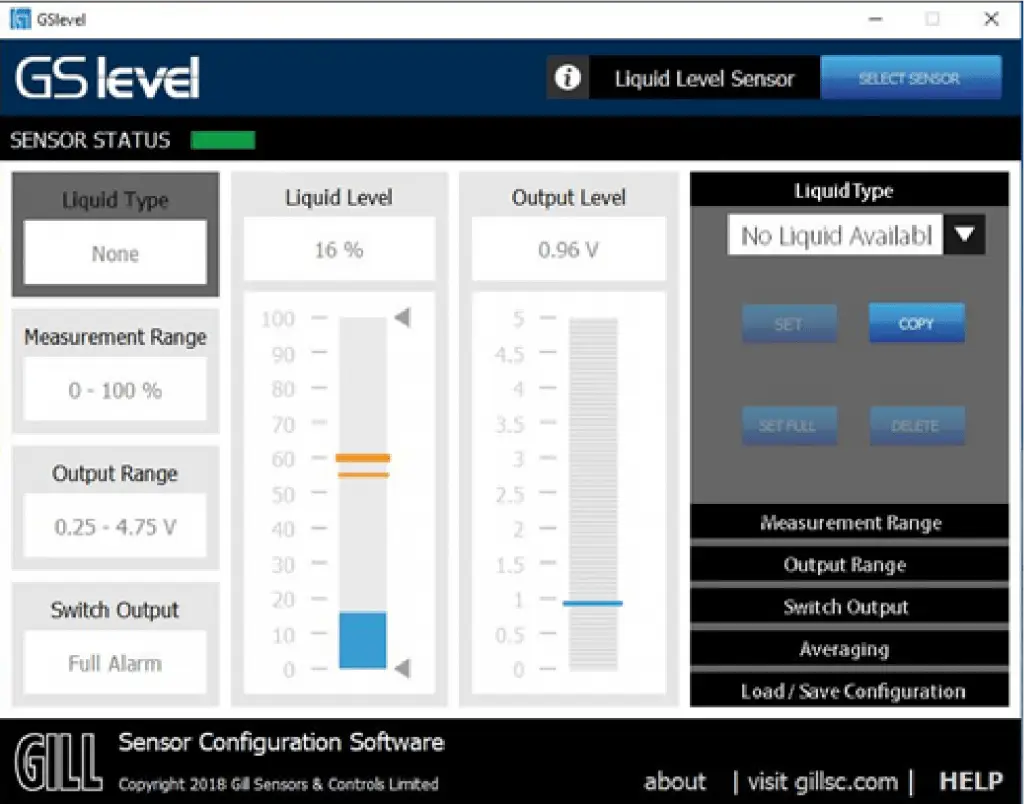

GSlevel software is designed for easy level sensor customisation and is free to download. The software allows control over output settings, minimum and maximum levels and alarm switch levels for ultimate adjustability.

GSlevel also allows the user to achieve a volumetric output using its tank profiling feature. Users can reconfigure the sensor using the simple configuration wizard or by uploading a CSV file to profile a cross-section of the data to gain a volumetric output.

Compatible products: LevelPro, LevelLite, LevelSlick and CatchTank level sensor.

Compatible operating systems: Windows® 7 or later

Gill has a number of applications to support older products and older operating systems. For more information please contact support@gillsc.com specifying

All new Gill level sensors come with a secondary output function which operates as a high or low level switch.

Class 1 powerboat level sensor provides real-time monitoring of ballast tanks at 200mph in some of the toughest environmental conditions

Gill liquid level sensors are installed into a fleet of locomotives to provide reliable real-time measurement of diesel fuel tanks exposed to severe weather conditions

Gill has designed and developed a custom heavy-duty hydraulic oil level sensor for installation on a new cement grinding roller mill prototype.

Liquid level sensors with marine systems compatibility accurately monitor hovercraft critical fluids

Maintaining consistent water levels in swimming pools in the heat of Hawaii is challenging. A solid-state liquid level sensor has been installed allowing constant monitoring and automatic top-up.

The Large Synoptic Survey Telescope (LSST) will use the world’s largest digital camera, requiring continuous refrigeration to -100°C. High performance liquid level sensors are required as part of this cooling system.

Robust, solid-state level sensors provide reliable coolant level information in harsh operating environments direct to the cab

Characteristics of sensor technologies used successfully in harsh environments

Float devices are a popular technology for measuring the level of liquids but electronic versions are also available for more sophisticated demands.

To explain capacitive liquid level sensing, we must first understand the concept of a capacitor (VIDEO 4.5 mins)

Commercial marine vessels are required to work hard and provide maximum availability to owners and operators. Gill sensors support this through high reliability and minimum maintenance requirement

There are many advantages of capacitive level measurement technology – here is a short summary of the main benefits…