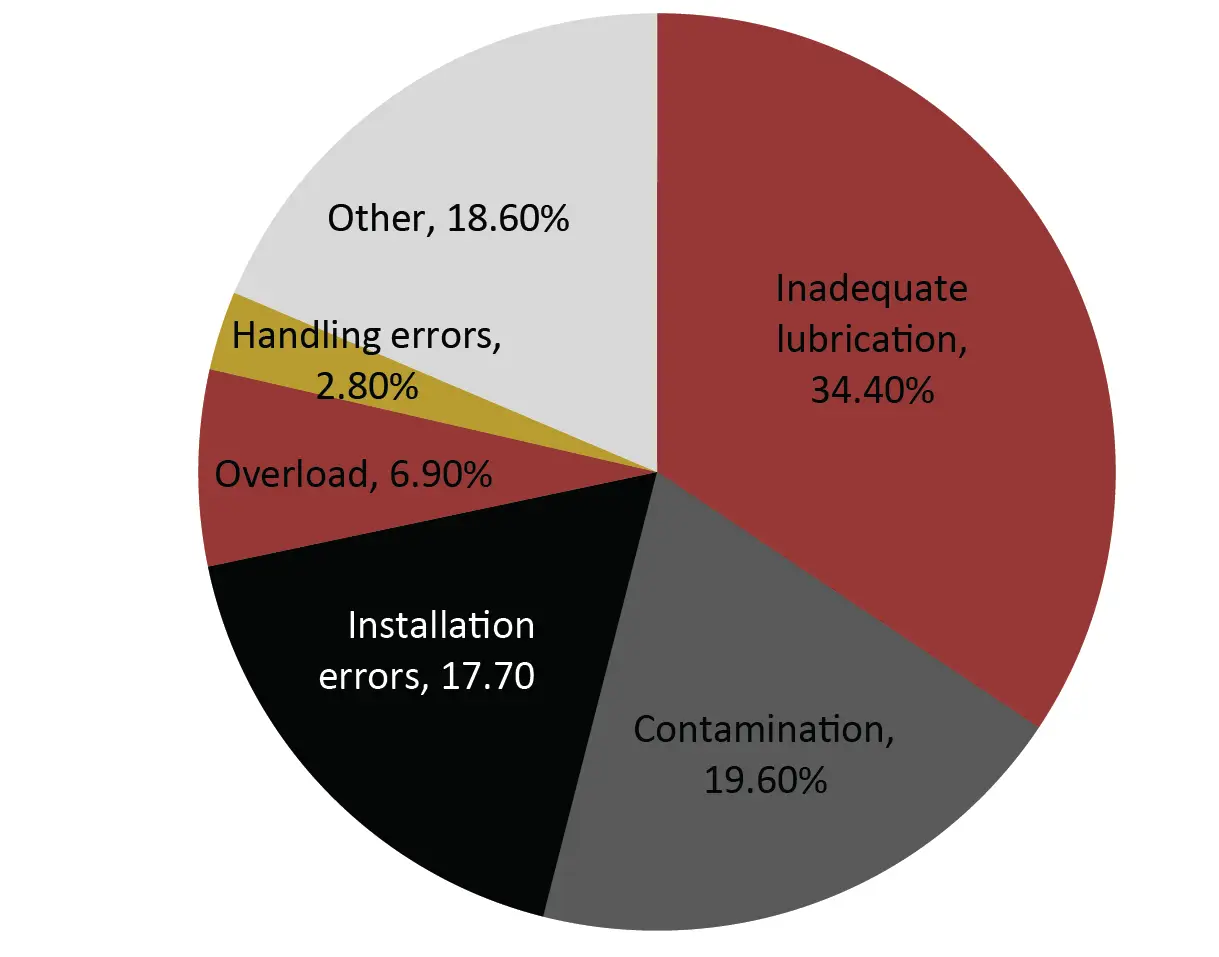

Rail axle wear monitoring

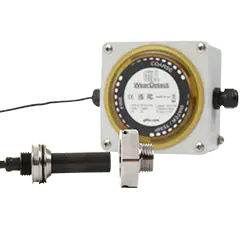

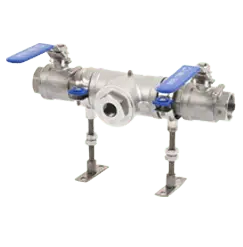

Real-time axle wear detection can prevent unexpected failure, minimise rail downtime and allow maintenance teams to focus resources on the highest priority items. Ferrous debris sensors provide essential real-time insight into axle health.