How -to Guide: Use an Open Collector Output

All new Gill level sensors come with a secondary output function which operates as a high or low level switch.

LevelSlick specialist level sensors measure challenging liquids in a range of applications where reliable low maintenance operation is important. LevelSlick’s PTFE coating makes it suitable for measuring difficult liquids including high viscosity water based varnishes, liquids containing solids and effluents as well as slurries and foaming liquids. LevelSlick is commonly used in water treatment and waste tanks as well as industrial storage and processing.

Designed & Manufactured by Gill Sensors & Controls in the UK, LevelSlick liquid level sensors provide reliability whatever the media. Conductive technology and a PTFE coating allow LevelSlick to combine a non-stick sensor with a design containing no holes or moving parts to block or stick. This ensures reliability and low maintenance requirements in materials normally difficult to measure. LevelSlick is compatible with suspended solids, flocculants, slurries, colloids, effluents and acidic fluids. The sensors are unaffected by films or build up that can occur on tank walls which can be problematic for capacitance based devices.

LevelSlick is often deployed where build up of residues or suspended solids from the liquid can result in unreliable or inaccurate measurements. LevelSlick remains accurate in these circumstances, preventing accidental overflow or tank draining when difficult or dangerous materials are being managed. The sensor probe has been engineered so it does not require additional mechanical support in the tank, whilst being robust enough to withstand any strong agitation that may be present. The single smooth probe facilitates the serviceability of the sensor should any cleaning be required, simply wipe down with alcohol wipes.

A tank profiling feature allows LevelSlick to provide accurate tank volume output results even in irregular tank shapes, essential for process inventory management.

Three output options are available for LevelSlick: Voltage maximum 0.25-10.0V DC (configurable), current 4-20mA, resistive 10-180 or 240-33 ohms.

Environmental protection to IP66/IP68/IP69k to EN60529

LevelSlick liquid level sensors have no moving parts and as a result are extremely reliable and accurate.

Gill LevelSlick liquid level sensors are supported by standard accessories to assist with specific installation requirements.

A USB lead (Type A to Micro B) allows connection of a LevelSlick liquid level sensor to a computer where the sensor can be setup and configured using GSlevel software.

Overview

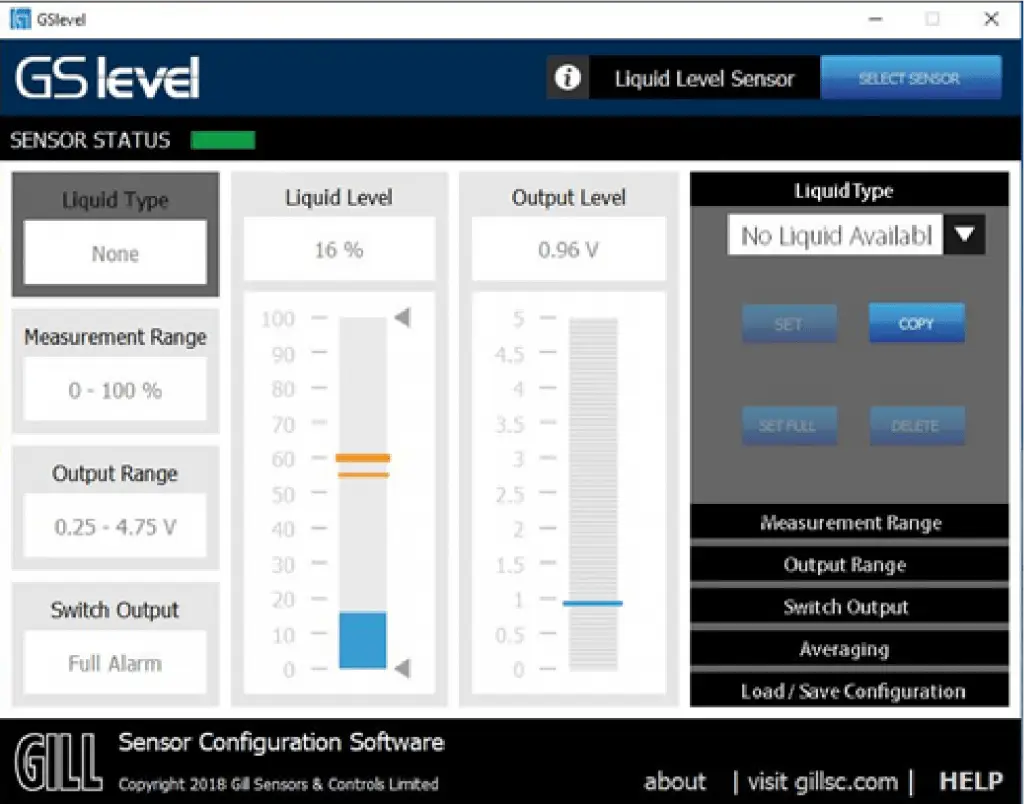

GSlevel software is designed for easy level sensor customisation and is free to download. The software allows control over output settings, minimum and maximum levels and alarm switch levels for ultimate adjustability.

GSlevel also allows the user to achieve a volumetric output using its tank profiling feature. Users can reconfigure the sensor using the simple configuration wizard or by uploading a CSV file to profile a cross-section of the data to gain a volumetric output.

Compatible products: LevelPro, LevelLite, LevelSlick and CatchTank level sensor.

Compatible operating systems: Windows® 7 or later

Gill has a number of applications to support older products and older operating systems. For more information please contact support@gillsc.com specifying

View our short videos to see how LevelSlick works.

Why LevelSlick is reliable in some of the toughest liquids, including slurries with suspended solids.

(1 mins)

Reliable level measurement with minimal cleaning/servicing.

(1.5 mins)

Reliable and accurate, fit-and-forget solution – LevelSlick explained.

(1.5 mins)

LevelSlick demonstration

(1 mins)

All new Gill level sensors come with a secondary output function which operates as a high or low level switch.

Level measurement of difficult, high viscosity materials such as varnishes requires specially developed non-stick sensors.

Measuring true water volumes in liquids containing flocculant, agitation, foaming etc requires a level sensor designed to be reliable and accurate under these conditions

Wastewater level monitoring in sewage treatment plants requires a sensor that can reliably cope with sludge, strong fluid flow while exposed to the environment

Blackwater level sensor with non-stick PTFE surface allows real-time marine waste water tank monitoring with minimum maintenance requirement

The solid, cavity-free sensing probe with a non-stick FEP coating prevents residue build-up in sludge and foul water which would lead to inaccurate liquid level readings